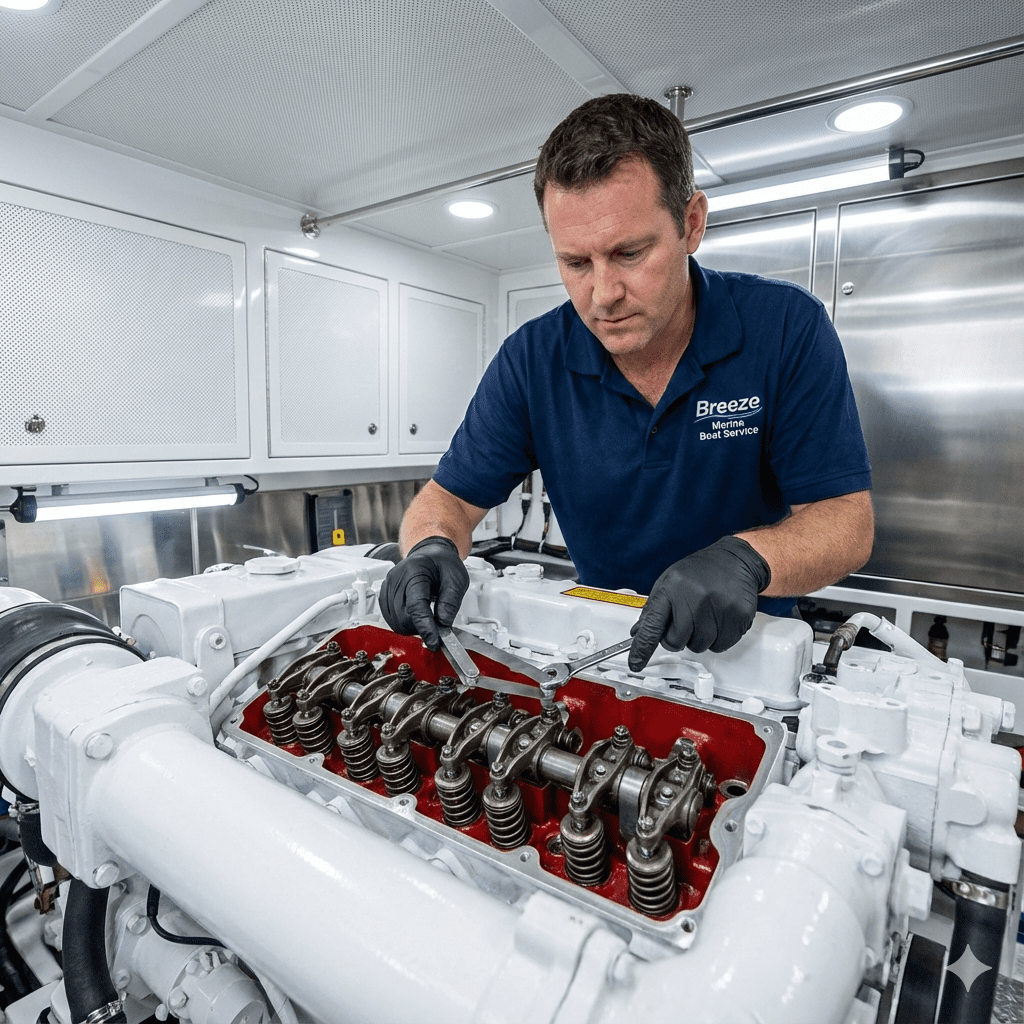

Valve Adjustment & Compression Testing

Restore Power.

Reduce Smoke.

Marine diesel engines require precise valve timing for peak efficiency. Incorrect lash leads to excessive smoke, noise, and internal damage.

The "Lash" Adjustment

Over time, the gap between the rocker arm and the valve stem changes. We use precision feeler gauges to reset this gap to factory specifications, ensuring valves open and close exactly when designed.

Symptoms of neglect

If your diesel is ticking loudly at idle, smoking excessively under load, or struggling to reach top RPM, it is highly likely your valves are out of adjustment.

Compression Health Check

A compression test is the definitive "EKG" for your engine. It measures the pressure in each cylinder, revealing the condition of rings, valves, and head gaskets without disassembly.

The Adjustment Protocol.

Meticulous execution for optimal combustion.

Cool Down

Valve adjustments must be performed on a "cold" engine (typically sitting overnight) to ensure accurate thermal tolerances.

Access

We remove the valve cover and manually rotate the engine to find Top Dead Center (TDC) for each cylinder in firing order.

Measure & Set

Using calibrated feeler gauges, we measure the gap and adjust the rocker arm screw and locknut to the precise factory spec.

Seal Up

We replace the valve cover gasket, torque the cover down, and run the engine to verify quiet operation and no leaks.

Inside the Engine.

Precision work that restores factory performance.

Diesel Expertise.

We service the leading marine diesel powerplants.

Common Questions

How often do valves need adjusting?

It varies by manufacturer, but typically every 500 to 1,000 hours. Check your owner's manual. Neglecting this can lead to burned valves.

Why do a compression test?

It's the best way to assess the overall health of an engine's core components (piston rings, valves) before buying a boat or if you suspect internal issues.

| Manufacturer | Breeze Marine Boat Service |

|---|

-

Boat Service$150.00

Boat Service$150.00 -

Marine Boat Service$150.00

Marine Boat Service$150.00