Marine Alternator Rebuild & High-Output Upgrades

Keep your boat running smoothly with our Boat Alternator Repair – Rebuild and Testing Service. Our expert technicians specialize in diagnosing and resolving issues with boat alternators, ensuring optimal performance on the water. Customers love our efficient service that saves time and money by avoiding the need for a full replacement.

Our comprehensive rebuild and testing service includes thorough inspection, component replacement, and quality assurance testing to guarantee a reliable alternator for your boat. Trust us to get your alternator back in top condition so you can enjoy uninterrupted adventures on the waves. Browse our What's New boat and Repair categories to discover more marine maintenance solutions.

Unlimited

Charge.

Modern boats are power-hungry. If your stereo, radar, and fridge are draining your batteries faster than you can charge them, your alternator is the bottleneck. We test, rebuild, and upgrade marine units to keep up with demand.

Bench Testing Diagnostics

Stop guessing. We remove your alternator and spin it up on our professional test bench. We measure exact voltage output and amperage under load to determine if it needs a rebuild or just a new regulator.

Premium Rebuilds

Better than new. We strip the unit down, clean the cases, re-dip the windings, and install heavy-duty marine bearings, brushes, and rectifier diodes designed to survive the saltwater environment.

High-Output Upgrades

Tired of weak charging at idle? We can often upgrade the stator and rotor inside your existing casing to boost output from a standard 60 amps to 100+ amps, keeping your house bank full.

The Rebuild Process.

Restoring reliability.

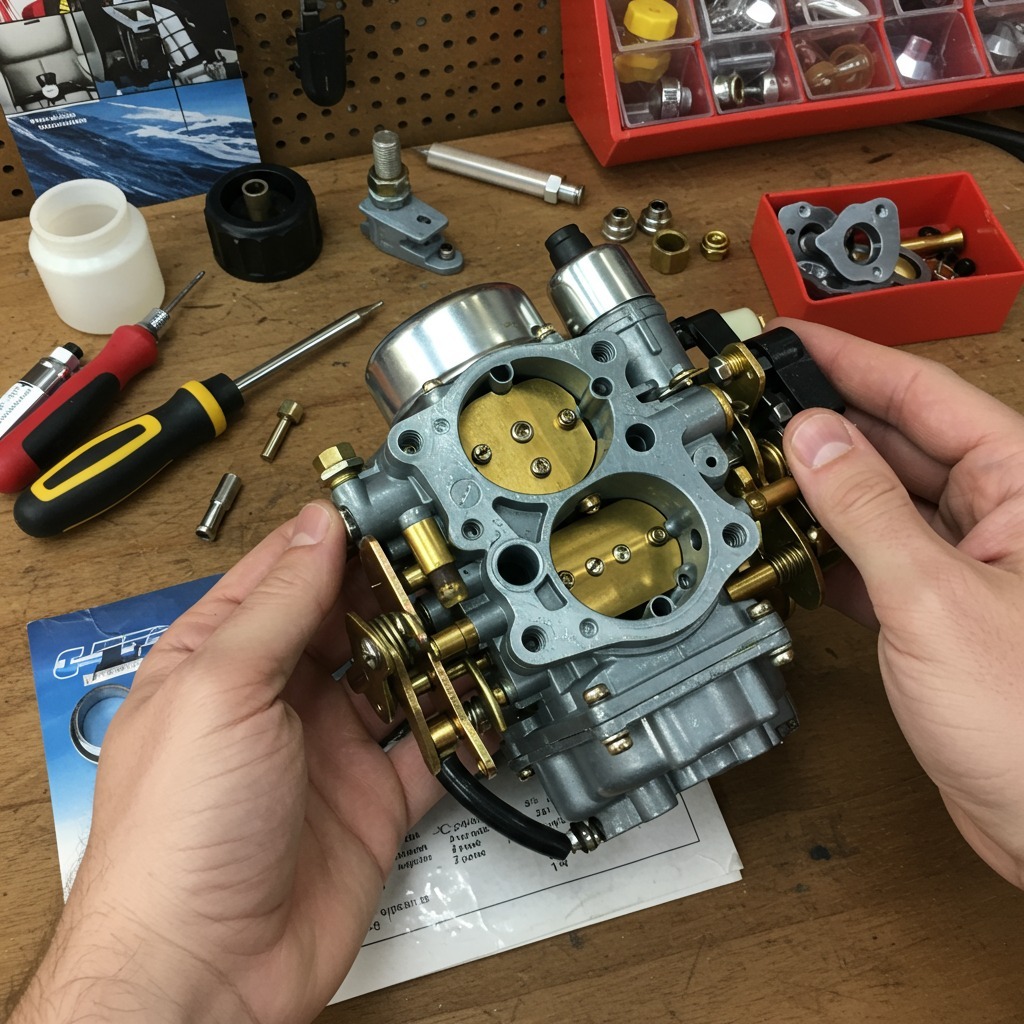

Teardown & Clean

We disassemble the unit completely. Casings are bead-blasted to remove corrosion, and internal copper windings are inspected for electrical shorts or heat damage.

Component Renewal

We replace high-wear items: brushes, slip rings, and bearings. We install marine-grade voltage regulators and heavy-duty rectifier diodes to handle high heat.

Winding Treatment

The copper stator and rotor windings are cleaned and re-coated with high-temperature insulating varnish to protect against saltwater intrusion and vibration.

Final Load Test

Before it goes back on your boat, we run it hard on the bench tester for 30 minutes under full load to ensure it maintains peak voltage when hot.

Services Available.

Powering your electronics.

Charging Specs.

Optimal performance.

Common Questions

Why rebuild instead of buying new?

A high-quality rebuild of your OEM unit using American-made components is often cheaper and far more reliable than buying a "brand new" cheap aftermarket clone from overseas.

Do I need a high-output alternator?

If you have added large stereo amplifiers, radar, multiple fridges, or electric downriggers, a standard 60-amp alternator likely cannot keep up with the demand.

| Manufacturer | Breeze Marine Boat Service |

|---|

-

Boat Service$150.00

Boat Service$150.00 -

Marine Boat Service$150.00

Marine Boat Service$150.00