Structural Fiberglass & Gelcoat Restoration

Our Fiberglass Hull Damage Repair kit is your solution for fixing cracks, chips, and delamination on your boat or watercraft. Sail smoothly knowing your vessel is in top shape, thanks to the strength and durability of our repair solution. Customers love how easy it is to use and the professional results it delivers, saving time and money on expensive repairs.

This repair kit is designed specifically for fiberglass surfaces, ensuring a seamless finish and long-lasting protection against water damage. Suitable for both DIY enthusiasts and professionals, our product is a must-have for all boat owners looking to keep their vessels in pristine condition.

Erase the

Damage.

Impacts, stress cracks, and delamination compromise both the value and safety of your vessel. We perform expert fiberglass structural repairs and precision gelcoat color matching to return your hull to a factory-new finish.

Structural Delamination

When the fiberglass layers separate, the hull creates "soft spots" that flex dangerously. We inject epoxy or cut out the rot, laying new biaxial glass to restore rock-solid rigidity to decks and transoms.

Gelcoat Color Match

White isn't just white. There are hundreds of shades of marine white. We custom tint our gelcoat to match your specific aged hull, ensuring the repair blends invisibly without a "patch" look.

Dock Rash & Gouges

Deep scratches expose the laminate to water intrusion (blisters). We grind out the damage, fill with high-strength fairing compound, and resurface the area for a seamless, watertight seal.

The Repair Process.

Artisan craftsmanship.

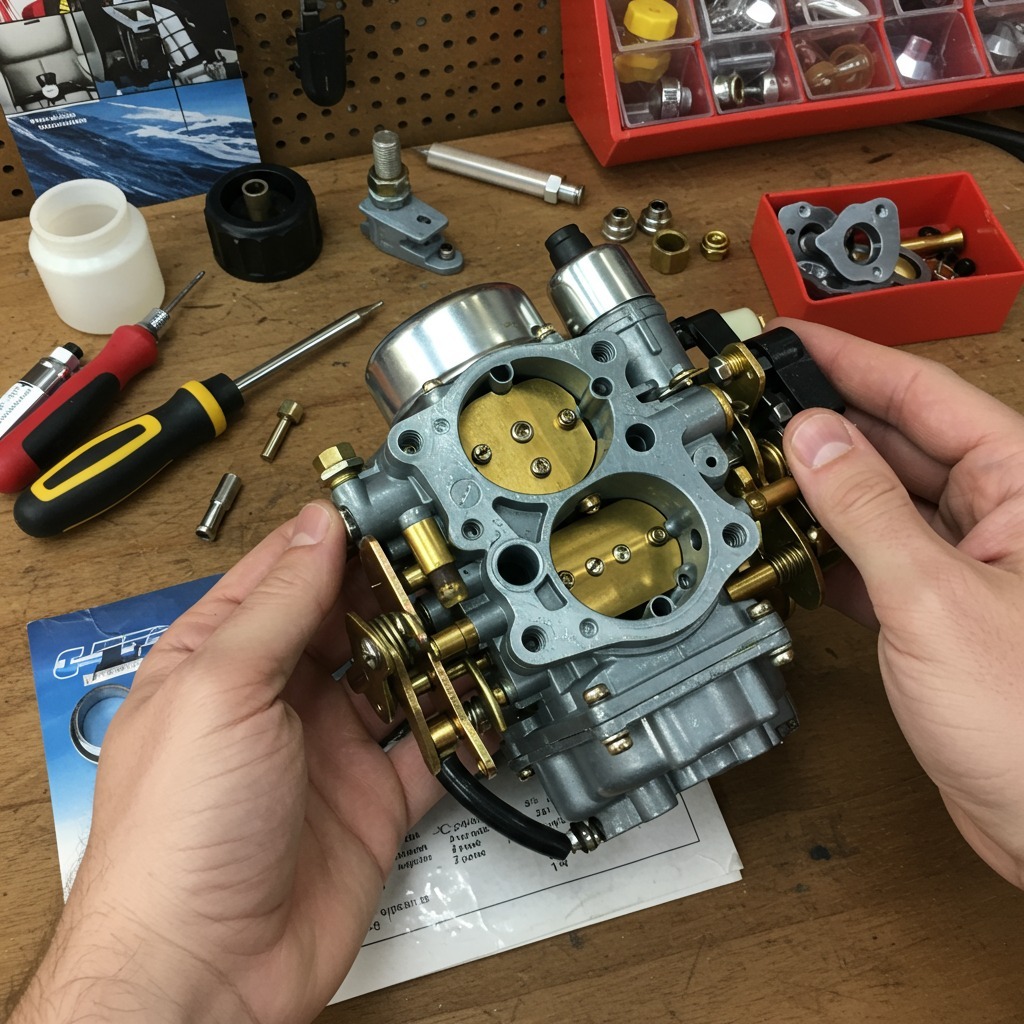

Grind & Prep

We bevel the damaged area to a 12:1 ratio. This provides a large surface area for the new fiberglass to bond chemically and mechanically to the old hull.

Lamination

We lay in new layers of 1708 biaxial cloth and marine resin (Polyester or Vinylester), building the thickness back up to match the original hull specs.

Fairing

We apply fairing compound and block sand by hand. This crucial step sculpts the curves, ensuring the repair is perfectly level with the surrounding surface.

Finish & Polish

We spray the final gelcoat layer, then wet-sand from 400 to 2000 grit, finishing with a high-speed compound buff to bring out a mirror shine.

Defects We Fix.

Restoring perfection.

Materials Used.

Chemistry matters.

Common Questions

Will the repair spot be visible?

Our goal is 99% invisibility. While aged gelcoat fades (making a perfect match difficult), we tint our materials to blend so well that you won't find it without pointing it out.

Is the repair as strong as the original?

Often stronger. By using modern Vinylester resins and biaxial cloth, the repaired section is frequently more durable and flexible than the original factory layup.

| Manufacturer | Breeze Marine Boat Service |

|---|

-

Boat Service$150.00

Boat Service$150.00 -

Marine Boat Service$150.00

Marine Boat Service$150.00