Oil Sample Analysis Engine Transmission Generator

The Engine

Blood Test.

Don't wait for a catastrophic failure. Oil analysis uses spectrographic testing to detect internal wear, leaks, and contamination months before symptoms appear.

Wear Metals

The lab measures microscopic metal particles in parts per million (PPM). High iron indicates cylinder wear; high lead or copper points to failing crankshaft or cam bearings.

Fluid Contamination

We detect what shouldn't be there. Coolant (glycol) in the oil suggests a blown head gasket. Diesel fuel dilution indicates leaking injectors or a high-pressure pump failure.

Oil Health

Is your oil doing its job? We test viscosity (thickness), soot levels, and oxidation. This tells us if you are changing your oil too soon, or waiting too long.

The Sampling Protocol.

Clean collection for accurate results.

Warm Up

We run the engine to operating temperature. This suspends contaminants in the oil, ensuring a representative sample.

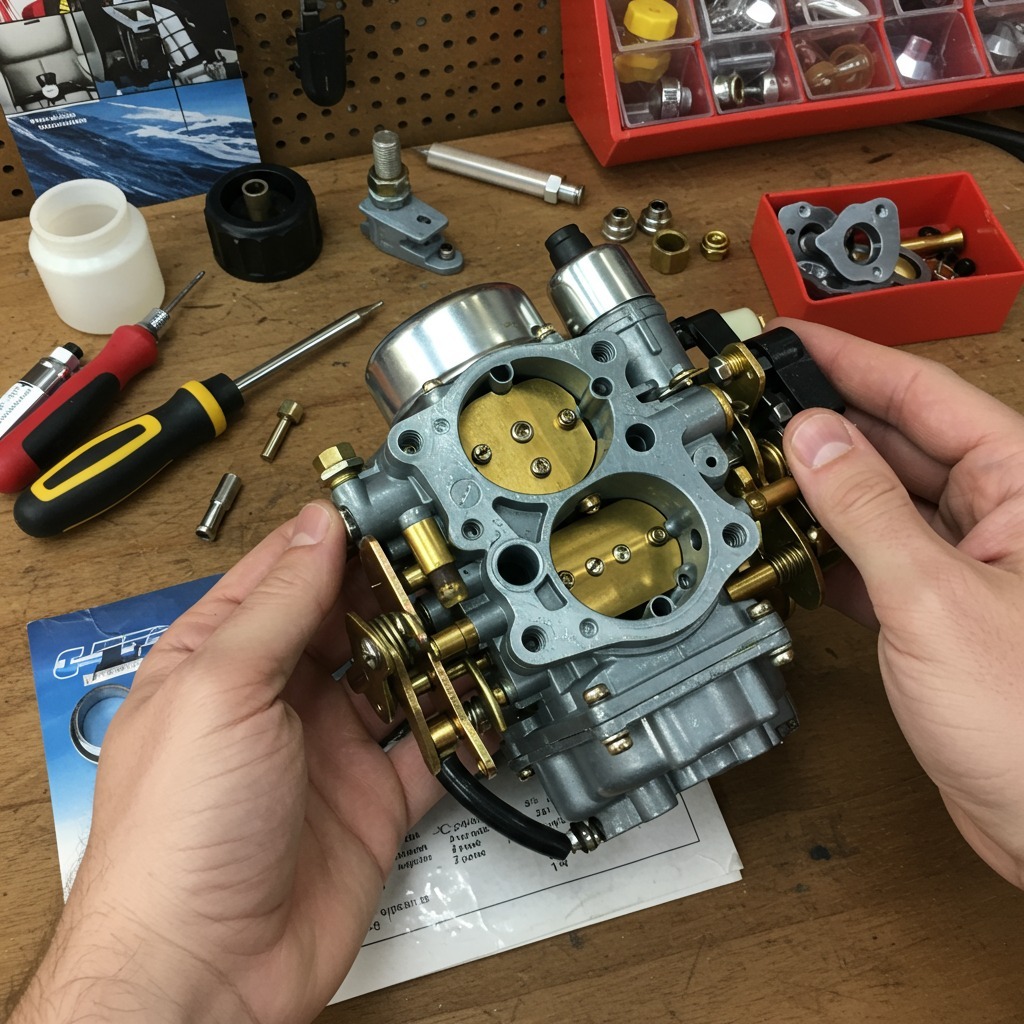

Live Draw

We use a sterile vacuum pump and tubing to draw oil directly from the sump or dipstick tube. We never sample from a drain pan.

Lab Transit

We label the samples with engine hours and type, then overnight them to an ISO-certified laboratory for testing.

Interpretation

You receive the raw data, but more importantly, our expert interpretation and actionable recommendations based on the results.

The Proof is in the Results.

Data-driven decisions for your drivetrain.

Systems We Test.

Comprehensive fluid analysis across the vessel.

Common Questions

Why not just change the oil?

Changing oil removes the evidence. If a bearing is failing, the metal is in the oil. Draining it without testing throws away the only early warning sign you'll get.

How long do results take?

Typical turnaround time from sample collection to receiving the digital report via email is 3 to 5 business days, depending on shipping and lab volume.

| Manufacturer | Breeze Marine Boat Service |

|---|

-

Boat Service$150.00

Boat Service$150.00 -

Marine Boat Service$150.00

Marine Boat Service$150.00