Cylinder Head Machining & Valve Job

Don't Re-Power.

Rebuild.

Loss of compression, overheating, or a blown head gasket doesn't always mean a new engine. Our Top-End Rebuild service restores factory tolerances to your cylinder heads, saving you thousands.

Precision Resurfacing

Overheating causes aluminum heads to warp. We machine the deck surface perfectly flat (within .001") to ensure the new head gasket seals tight and holds compression under load.

3-Angle Valve Job

We don't just lap valves; we cut them. A multi-angle cut on the valve seat improves airflow and sealing, restoring lost horsepower and improving fuel economy.

Pressure Testing

Before spending a dime on parts, we pressure test the casting to check for internal cracks. If the head is cracked, we tell you immediately so you don't waste money fixing a dead part.

The Rebuild Protocol.

Cleaning, Machining, Assembling.

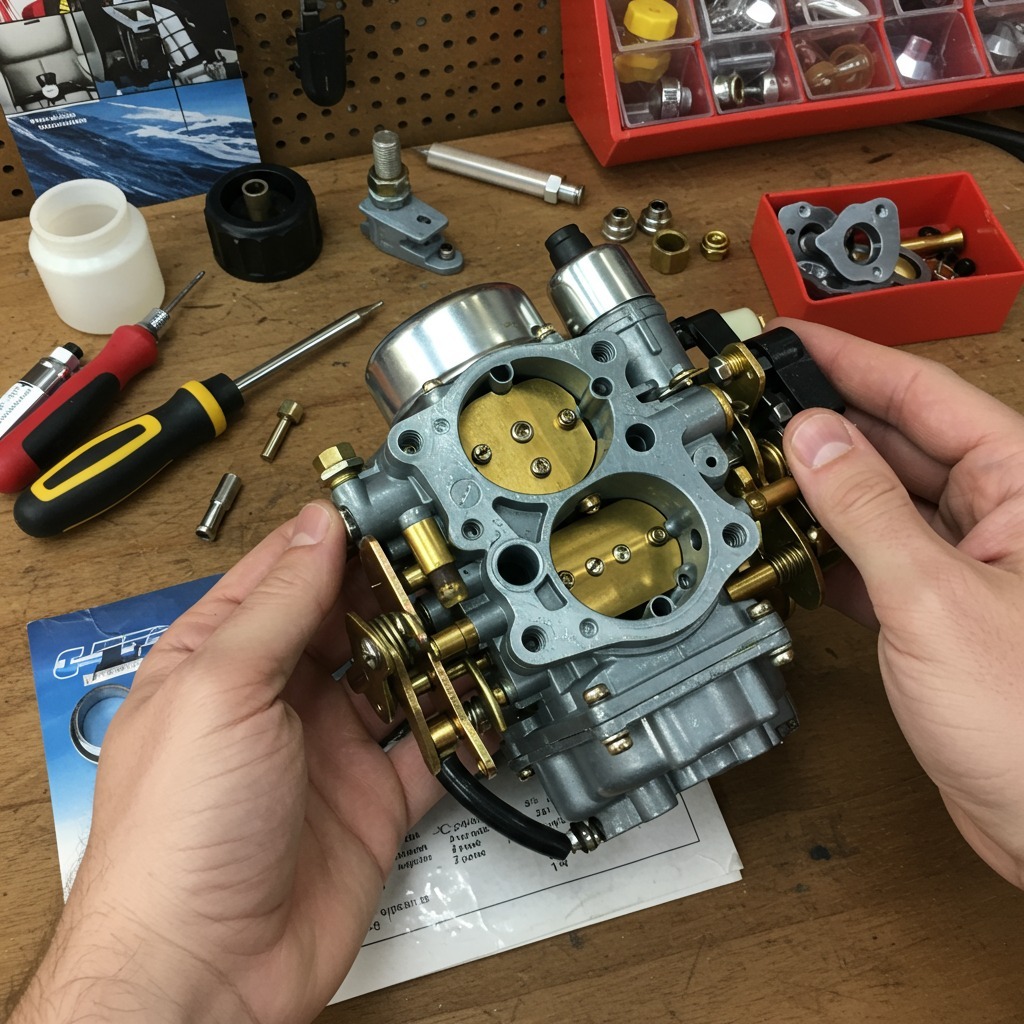

Teardown & Clean

We disassemble the head, remove valves and springs, and hot-tank clean the casting to remove decades of carbon and scale.

Magnaflux / Test

We use magnetic particle inspection (Iron) or dye penetrant (Aluminum) to hunt for invisible cracks between the valves.

Machine Work

The deck is milled flat. Valve guides are replaced if worn. Seats are cut. This creates a "better than new" foundation.

Assembly

We install new valve stem seals (to stop smoking), assemble springs to correct height, and vacuum test the ports to verify the seal.

Restored Power.

The heart of your engine, renewed.

Capabilities.

From Outboards to Big Diesels.

Common Questions

How do I know if I need this?

Symptoms include overheating at high RPM, white smoke (steam) in exhaust, water in your oil (milkshake), or low compression in one or more cylinders.

Is it worth fixing an old head?

Yes, if the casting isn't cracked. A valve job and resurface costs significantly less than a new cylinder head assembly, and restores the engine to 100% functionality.

| Manufacturer | Breeze Marine Boat Service |

|---|

-

Boat Service$150.00

Boat Service$150.00 -

Marine Boat Service$150.00

Marine Boat Service$150.00