Lower Unit Reseal & Pressure Testing

Hold Pressure.

Keep Water Out.

Milky gear lube is the first sign of disaster. Water intrusion rusts gears and destroys bearings. We use precision pressure and vacuum testing to identify failing seals before they cost you a lower unit.

Pressure & Vacuum

We don't just guess. We drain the unit and pressurize it to 10-15 PSI to find leaks that let oil out. Then we pull a vacuum to find leaks that suck water in (cooling phase). If it holds, your gears are safe.

Complete Reseal

When a leak is found, we perform a complete teardown. We replace the prop shaft seals, drive shaft seals beneath the water pump, shift shaft seals, and all carrier O-rings with OEM quality parts.

Leak Detection

Using soapy water and UV dye, we pinpoint the exact failure point. Is it a fishing line cut on the prop shaft? A corroded shift seal? We identify the root cause so the new seals last.

The Reseal Procedure.

A rigorous defense against saltwater.

Drain & Pressure Test

We drain the old lube (checking for water/metal) and hook up the pressure tester. We inflate to 12 PSI and watch for a drop. A drop = a leak.

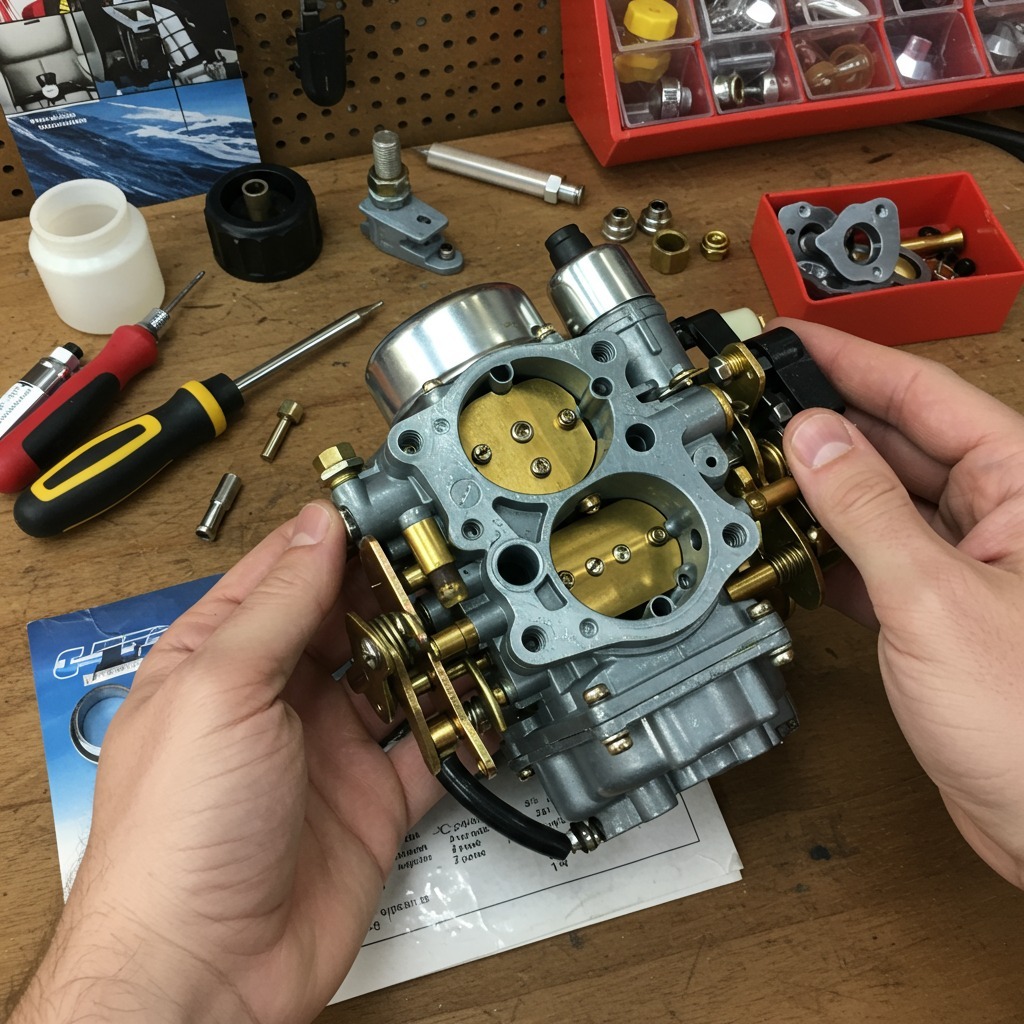

Disassembly

We pull the bearing carrier and water pump base. We inspect the shafts for grooving (which ruins new seals) and polish them if necessary using Speedi-Sleeves if needed.

Seal Installation

Using specialized drivers, we install new double-lip seals. We ensure the springs face the correct direction (oil side vs water side) for maximum protection.

Final Verification

Before adding oil, we re-pressurize the unit. It must hold 10-15 PSI for at least 15 minutes with zero drop. Only then do we fill it with synthetic lube.

Sealed Tight.

Quality components make the difference.

Test Specs.

We follow factory standards.

Common Questions

What causes seals to fail?

The #1 culprit is fishing line wrapped around the prop shaft, which cuts the rubber. Age, heat cycling, and sitting dry for long periods also cause the rubber to crack.

Can I just refill the oil and ignore it?

Absolutely not. Water is heavier than oil and settles at the bottom, rusting the gears and bearings. Ignoring a leak guarantees a complete lower unit failure.

| Manufacturer | Breeze Marine Boat Service |

|---|

-

Boat Service$150.00

Boat Service$150.00 -

Marine Boat Service$150.00

Marine Boat Service$150.00