Distributor Cap, Rotor & Spark Plug Replacement

The Spark

of Life.

A misfiring engine ruins a day on the water. We replace corroded ignition components with marine-grade parts to restore power, smoothness, and reliability.

The "Green Death"

Marine air causes verdigris corrosion on the aluminum contacts inside standard distributor caps. This green buildup blocks the spark, causing rough idle and stalling.

Restored Power

Worn spark plugs require higher voltage to fire, straining your coil. Fresh plugs and a clean rotor ensure instant throttle response and better fuel economy.

Marine Grade Only

We never use auto parts. We install caps with solid brass contacts (not aluminum) and ignition-protected components designed to prevent bilge explosions.

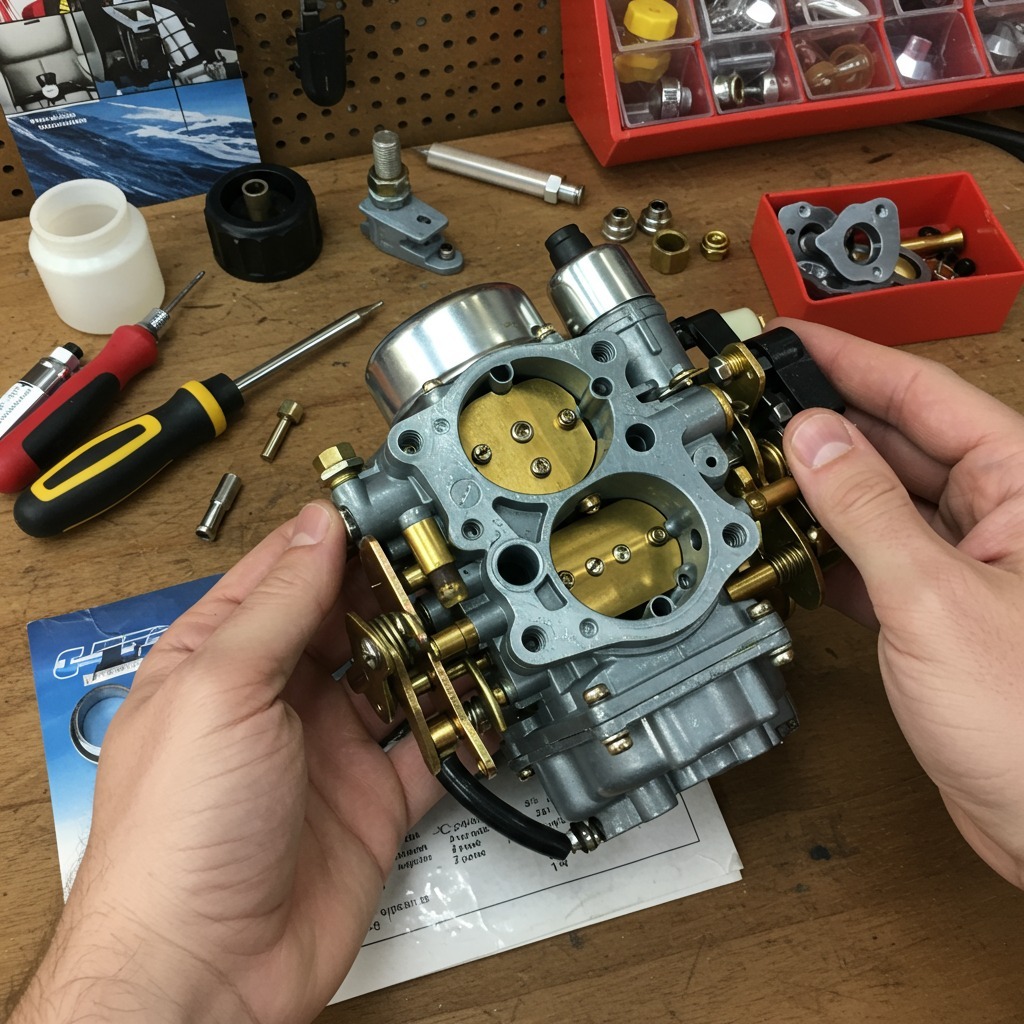

The Tune-Up Protocol.

Systematic replacement for optimal firing.

Inspect

We remove the old cap and inspect for "carbon tracking" (arcing lines) and moisture intrusion, which indicate bigger issues.

Plug Gap

We don't trust the box. We verify and set the precise electrode gap on every new spark plug before installation.

Install

We install the new rotor, cap, and plugs, applying dielectric grease to boots to seal out moisture and prevent future corrosion.

Timing

On applicable engines, we use a timing light to check and set the base ignition timing to factory specifications.

Smooth Idle.

Feel the difference at the helm.

Component Quality.

We use the brands that built your engine.

Common Questions

How often should this be done?

We recommend inspecting the cap annually. In saltwater, caps and rotors should generally be replaced every 100 hours or every 2 years, regardless of appearance.

Can I use car parts?

**No.** Automotive distributors are not "ignition protected." If you have fuel vapors in your bilge, a car distributor can ignite them and cause an explosion.

| Manufacturer | Breeze Marine Boat Service |

|---|

-

Boat Service$150.00

Boat Service$150.00 -

Marine Boat Service$150.00

Marine Boat Service$150.00