Boat Alternator Repair Marine Rebuild and Charging System Testing

Boat Alternator Repair – Rebuild and Testing Service

The alternator is the heart of your boat’s charging system. It keeps your batteries charged and powers essential electronics while the engine is running. A faulty alternator can cause low voltage, dead batteries, or even engine shutdown. This post explains signs of alternator failure, what professional repair includes, and how rebuilding can save your boating trip.

Why a Working Alternator Matters on the Water

Boats rely heavily on DC power—for navigation, lighting, bilge pumps, radios, and engine control. If your alternator fails, your battery won’t recharge, and you could lose critical systems. Diagnosing charging problems quickly is key to avoiding costly breakdowns.

Common symptoms of alternator failure:

- Battery warning light or voltage alarm

- Dim lights or fluctuating brightness

- Electronics cutting out while underway

- Burning smell or hot alternator casing

- Low voltage readings on multimeter (< 13V when running)

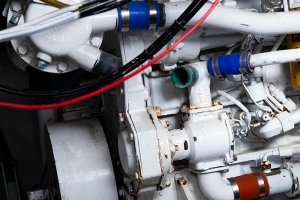

Key Parts of the Marine Alternator System

1. Alternator (Stator, Rotor, Diodes)

Generates AC power and converts it to DC. Wear or failure can occur in bearings, brushes, or internal regulators.

2. Voltage Regulator

Controls output voltage to protect batteries. May be internal or external. Faulty regulators lead to overcharging or undercharging.

3. Drive Belt

Connects alternator to engine crankshaft. A loose or slipping belt reduces alternator RPM and charging efficiency.

4. Battery Bank

The alternator charges your batteries—faulty batteries can mimic alternator problems.

Pro tip: Always test your alternator output with the engine running—don’t rely on battery voltage alone.

What Alternator Repair or Rebuild Involves

A full-service alternator rebuild or replacement may include:

- Alternator bench testing (under load)

- Cleaning and replacing bearings, brushes, and diodes

- Voltage regulator testing or replacement

- Drive belt inspection and tension adjustment

- Charging system analysis (batteries, fuses, isolators)

Common repair scenarios:

- Worn brushes or burned-out stator windings

- Corroded terminals or broken ground straps

- Overheating due to saltwater damage

- Alternator output drops at idle or under load

Alternator Service for Inboard and Outboard Engines

At Breeze Marine Boat Service, we repair and rebuild marine alternators for:

- Inboard gasoline and diesel engines (MerCruiser, Cummins, Volvo Penta)

- Outboard alternator-equipped engines (Yamaha, Mercury, Suzuki)

- High-output alternators for house battery banks and inverters

We use OEM and marine-grade rebuild kits and test every alternator under load before reinstalling.

How to Maintain a Healthy Charging System

- Check belt tension and condition every 50 engine hours

- Clean alternator vents and ensure dry installation area

- Inspect charging cables and terminal corrosion regularly

- Test alternator voltage every season (13.5V–14.6V range)

- Avoid long engine idling with high electrical load

Boat Alternator Repair Near You

If you're in Long Beach, San Pedro, Marina del Rey, or Huntington Harbor, our mobile marine techs can:

- Diagnose charging system and battery issues

- Remove, rebuild, and reinstall alternators

- Test voltage output and replace regulators or belts

Contact Breeze Marine Boat Service for fast, certified alternator diagnostics and marine charging system repair—keep your boat powered and your batteries protected.